Your 5s manufacturing plant images are available. 5s manufacturing plant are a topic that is being searched for and liked by netizens today. You can Find and Download the 5s manufacturing plant files here. Get all royalty-free images.

If you’re searching for 5s manufacturing plant images information connected with to the 5s manufacturing plant interest, you have pay a visit to the right blog. Our website frequently provides you with suggestions for refferencing the highest quality video and image content, please kindly surf and locate more enlightening video articles and graphics that fit your interests.

5s Manufacturing Plant. 5s in lean manufacturing lean manufacturing is a way of thinking about productive systems with a focus on reducing the unnecessary — that is, eliminating wasted materials, effort, and time. A study on implementation of 5s in a product manufacturing company drastically reduced the inspection time of components and number of accidents [5]. This 5s audit checklist is a tool used by area supervisors or plant managers to perform monthly or quarterly audits. 5s is a formulaic method you can use to straighten and organize a work area.

Got Boondoggle? 5S Footprints on the Manufacturing Floor From gotboondoggle.blogspot.com

Got Boondoggle? 5S Footprints on the Manufacturing Floor From gotboondoggle.blogspot.com

In practice this would see raw ingredients sorted into categories and those that aren’t regularly used removed. As a 5s audit form, this checklist can help ensure that 5s principles and set standards are being followed and implemented by workers. Everything has a place and everything in its place. 5s is a formulaic method you can use to straighten and organize a work area. This approach helps to improve overall productivity, quality, and profits. To be successful in implementing 5s (sort, set, shine, standardize, sustain), audits must be conducted and four simple rules followed:

The 5s methodology is a proven set of principles to make your manufacturing plant more streamlined, efficient, and productive.

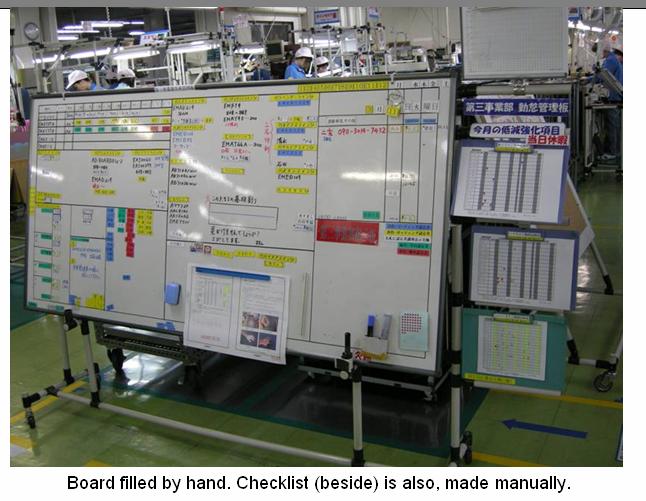

Many assembly plants are adopting the 5s organizational and housekeeping methodology as part of their continuous improvement and lean manufacturing processes. The 5s are sort, set, shine, standardize & sustain. This system consists of five pillars—sort, set in order, shine, standardize, sustain—that make maintaining the workplace in good condition a visual process. Normally in step 1, we only do the first three steps of 5s (sort, set/store & shine) 5s implementation delivers a method to reorganize layout and to develop discipline. Many assembly plants are adopting the 5s organizational and housekeeping methodology as part of their continuous improvement and lean manufacturing processes.

Source: bluestar-mould.com

Source: bluestar-mould.com

The 5s is a technique to keep the workplace organized at all times. 5s seems to be the way of life rather than just a routine. About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators. Using 5s reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on lean 6s safety ), and otherwise improves your production process and work environment. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement.

Source: productoo.com

Source: productoo.com

Normally in step 1, we only do the first three steps of 5s (sort, set/store & shine) Success stories are being displayed (i.e. To create a better understanding of the 5s method, it is important for business owners to learn the reasons why it should be made a part of the inner. The 5s methodology is a simple way to ensure compliance with these regulations, and every aspect of a brewery or brewpub will benefit from the application of 5s lean manufacturing. Safety is often said that it is implied within 5s that everything should be done with safety as the number one priority, but to ensure that is the case, safety is added as an additional s.

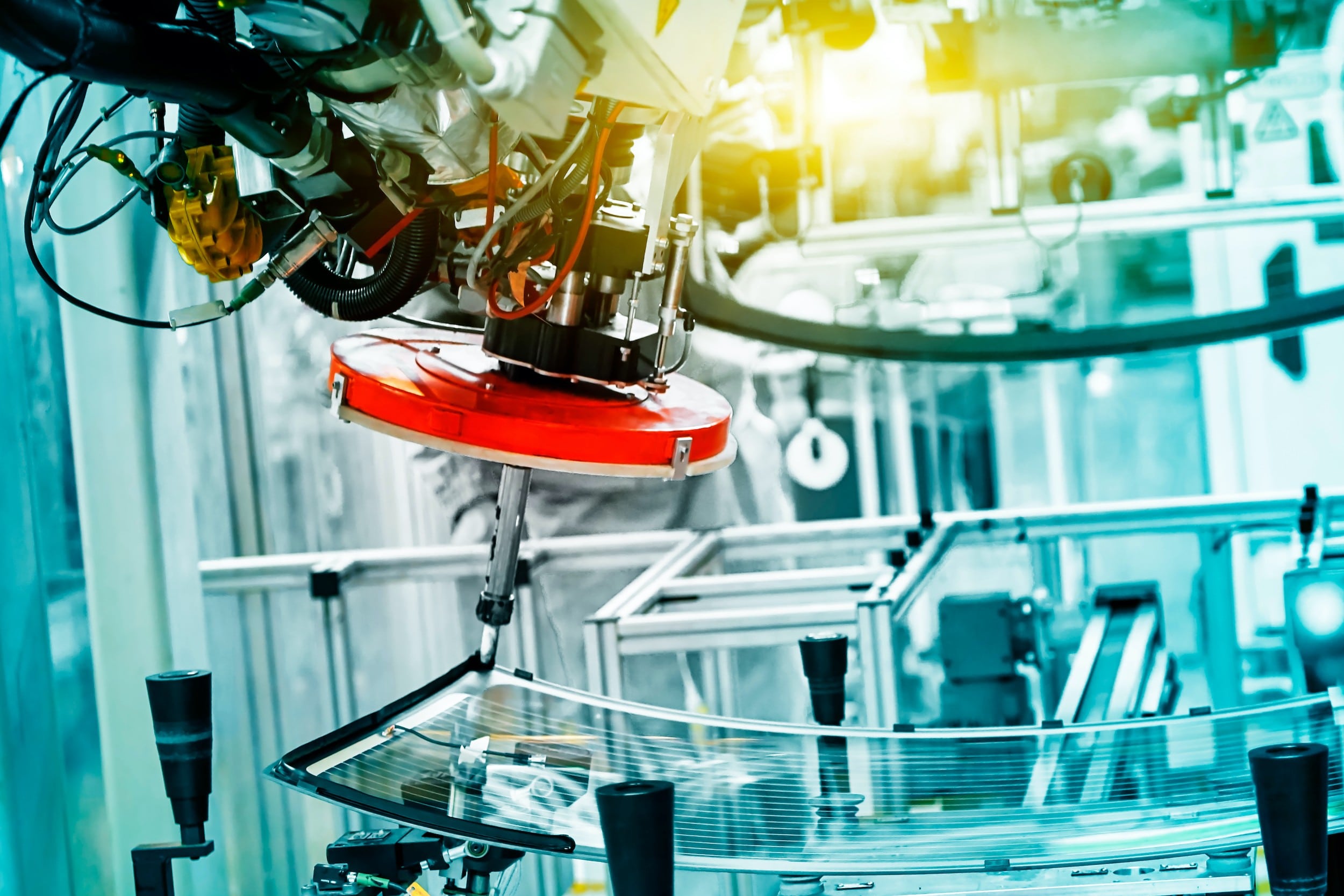

Source: worldautomobilevehicle.blogspot.com

Source: worldautomobilevehicle.blogspot.com

To create a better understanding of the 5s method, it is important for business owners to learn the reasons why it should be made a part of the inner. 5s implementation delivers a method to reorganize layout and to develop discipline. Regular audits are carried out using checklists and measures. The term 5s refers to 5 pillars of visual workplace as. About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators.

Source: bit-tech.net

Source: bit-tech.net

High precision equipment is bought, but not maintained. Using 5s reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on lean 6s safety ), and otherwise improves your production process and work environment. Seiri (sort) in a craft brewery. Similar to other strategies, however, effectiveness depends on ongoing verification and writing good questions. This approach helps to improve overall productivity, quality, and profits.

Source: komponentenwerk.com

Source: komponentenwerk.com

5s seems to be the way of life rather than just a routine. The 5s methodology is easy for everyone to start using. A 5s approach provides you with the opportunity to rethink the layout of the work cell, whether front line production, storage, or office. The idea is that safety is the ‘honory’ 6th s. When a jig or fixture is needed, it cannot be found.

Source: drillco.com

Source: drillco.com

As a 5s audit form, this checklist can help ensure that 5s principles and set standards are being followed and implemented by workers. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement. Each kit contains an assortment of our most popular floor and workbench marking supplies. Reasons to implement the 5s approach in manufacturing businesses. The acronym 5s stands for the five japanese words seiri (organization), seiton (neatness), seiso (cleanliness), seiketsu (standardization),.

Source: paultan.org

Source: paultan.org

A detailed study of 5s implementation makes it evident that it is a comprehensive working model for industries and other manufacturing businesses. The 5s is a technique to keep the workplace organized at all times. Everyone knows his responsibilities, when and how. Using 5s reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on lean 6s safety ), and otherwise improves your production process and work environment. Manufacturing plants using amts are more likely to use 5s 5s methodology has been considered as a prerequisite for an effective quality assurance system (dale, 1999).

Source: shmula.com

Source: shmula.com

The original concept was developed by osada in the early 1980s. 5s is a powerful lean manufacturing approach to improving safety, quality and efficiency on the plant floor. The morale of associates is poor and the plant is doomed for trouble. Each kit contains an assortment of our most popular floor and workbench marking supplies. Using 5s reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on lean 6s safety ), and otherwise improves your production process and work environment.

Source: craftforce.com

Source: craftforce.com

Manufacturing plants using amts are more likely to use 5s 5s methodology has been considered as a prerequisite for an effective quality assurance system (dale, 1999). Many assembly plants are adopting the 5s organizational and housekeeping methodology as part of their continuous improvement and lean manufacturing processes. 5s the secret to japanese success what problems do u commonly encounter at your workplace high absenteeism high turnover demotivated employees disordered/ cluttered environment mistakes/errors the solution to all these problems is 5s 5s housekeeping technique productivity and safety enhancement technique idea behind 5s in order to achieve high levels of quality,. 5s is called 5s because their are 5 steps and each step begins with the letter s. 2.1 | 5s in manufacturing industries.

Source: youtube.com

Source: youtube.com

5s in lean manufacturing lean manufacturing is a way of thinking about productive systems with a focus on reducing the unnecessary — that is, eliminating wasted materials, effort, and time. The original concept was developed by osada in the early 1980s. A 5s approach provides you with the opportunity to rethink the layout of the work cell, whether front line production, storage, or office. Sps engineering has been operated without knowledge of 5s principles. The other options to include with 5s are safety, security and spirit.

Source: fastcodesign.com

Source: fastcodesign.com

Reasons to implement the 5s approach in manufacturing businesses. The 5s are sort, set, shine, standardize & sustain. The 5s is a technique to keep the workplace organized at all times. The main goal of 5s is to help companies create safe, neat,. It doesn’t require any technical analysis and can be implemented globally in all types of companies, ranging from manufacturing plants to offices, small businesses to large multinational organizations — and in both private and public sectors.

Source: pinterest.fr

Source: pinterest.fr

5s fits naturally here, because it works toward a streamlined, organized, and clean workplace. The 5s are sort, set, shine, standardize & sustain. The 5s methodology is easy for everyone to start using. To create a better understanding of the 5s method, it is important for business owners to learn the reasons why it should be made a part of the inner. The term 5s refers to 5 pillars of visual workplace as.

Source: pinterest.com

Source: pinterest.com

High precision equipment is bought, but not maintained. Many assembly plants are adopting the 5s organizational and housekeeping methodology as part of their continuous improvement and lean manufacturing processes. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement. About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators. The 5s system of visual management has improved organization and efficiency in many workplaces including manufacturing environments and offices.

Source: macleanfogg.com

Source: macleanfogg.com

5s is a system to reduce waste and optimize productivity by maintaining an orderly workplace and providing visual cues to assemblers. Each kit contains an assortment of our most popular floor and workbench marking supplies. It is particularly prominent in manufacturing, warehouses, heavy equipment, construction, healthcare and laboratory. The other options to include with 5s are safety, security and spirit. Success stories are being displayed (i.e.

Source: gotboondoggle.blogspot.com

Source: gotboondoggle.blogspot.com

The 5s practice is a technique used to establish and maintain quality environment in an organization. The 5s system of visual management has improved organization and efficiency in many workplaces including manufacturing environments and offices. The term 5s refers to 5 pillars of visual workplace as. 5s checklists, schedules and routines are defined and being used. The other options to include with 5s are safety, security and spirit.

Source: toughnickel.com

Source: toughnickel.com

It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement. 2.1 | 5s in manufacturing industries. The 5s practice is a technique used to establish and maintain quality environment in an organization. Everyone knows his responsibilities, when and how. Success stories are being displayed (i.e.

Source: igmasonrysupport.com

Source: igmasonrysupport.com

This 5s audit checklist is a tool used by area supervisors or plant managers to perform monthly or quarterly audits. Similar to other strategies, however, effectiveness depends on ongoing verification and writing good questions. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement. 5s is a powerful lean manufacturing approach to improving safety, quality and efficiency on the plant floor. Ehs today calls it ‘the place where safety and lean meet’.

Source: pinterest.co.uk

Source: pinterest.co.uk

About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators. In practice this would see raw ingredients sorted into categories and those that aren’t regularly used removed. 5s is called 5s because their are 5 steps and each step begins with the letter s. The idea is that safety is the ‘honory’ 6th s. The other options to include with 5s are safety, security and spirit.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title 5s manufacturing plant by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.