Your Alcohol processing plant images are ready. Alcohol processing plant are a topic that is being searched for and liked by netizens now. You can Find and Download the Alcohol processing plant files here. Download all royalty-free images.

If you’re searching for alcohol processing plant pictures information linked to the alcohol processing plant interest, you have come to the right blog. Our website always provides you with suggestions for seeking the maximum quality video and image content, please kindly search and locate more enlightening video content and graphics that fit your interests.

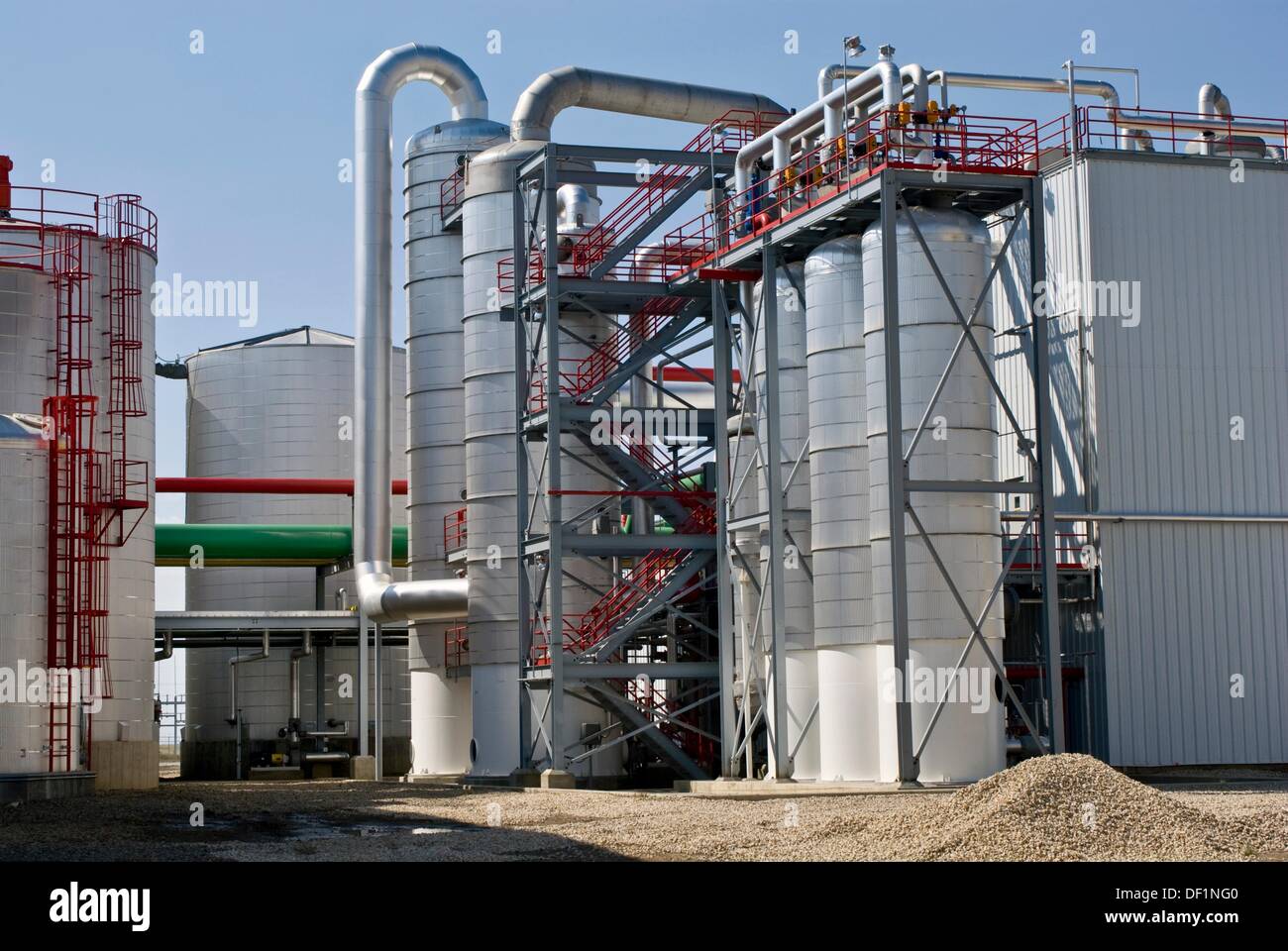

Alcohol Processing Plant. This technology from johnson matthey and dow global technologies, inc., a subsidiary of the dow chemical company (dow), offers licensees. A process for producing isopropyl alcohol by hydrating directly propylene and water in the presence of a strong acid solid catalyst which includes feeding continuously propylene, water which is the same as or more than propylene in terms of mole, and a saturated hydrocarbon (propane, butane and the like) to a reactor in which the above solid catalyst is filled or. The alcohol from the top of the column is passed through a dehydration system where the remaining water will be removed. Fuel ethanol plants and fuel alcohol plants are two different categories of alcohol processing plants.

Emerson’s PlantWeb® architecture provides flexible From emerson.com

Emerson’s PlantWeb® architecture provides flexible From emerson.com

A primary industrial alcohol is ethanol, or ethyl alcohol (c2h5oh). Alcohol extraction is a process of removing essential oils, fats, and other chemical compounds from plants. The alcohol from the top of the column is passed through a dehydration system where the remaining water will be removed. However, as heat is evolved during the fermentation process, the temperature in the fermenter gradually increases and is controlled and maintained at the above indicated range by means of cooling coils or by spraying cold water around the fermenter. The process of alcoholic fermentation is one of the oldest processes and is known as the most important of the industrial fermentations. Alcohol waste stream is heated and distillated in a stripper column to increase the ethanol content.

Located in jilin city in northeast china, this production line for bioethanol was officially commissioned in november 2003 after an implementation period of 22 months.

Alcohol extraction is by no means exclusive to cannabis. Available for immediate delivery and competitively priced. •azeotroping agent is feed near the top of column c106 via stream 23 which is produce in drying column c107. Ethanol, also known as ethyl alcohol, drinking alcohol or grain alcohol, is a flammable, colorless, mildly toxic chemical compound, and is best known as the alcohol found in alcoholic beverages. Any plant as a matter of fact. Johnson matthey has licensed the greatest number of plants worldwide for the production of natural detergent alcohols (nda), also known as fatty alcohols.

Source: mck.bg

Source: mck.bg

Results are shown in fig. However, of the many possible ways to use alcohol to extract material from plants, only a few work well with cannabis. , identification and selection of plant, process, equipment, general guidance, startup help, technical and commercial counseling for setting up new. Ethanol, also known as ethyl alcohol, drinking alcohol or grain alcohol, is a flammable, colorless, mildly toxic chemical compound, and is best known as the alcohol found in alcoholic beverages. •cbm or azeotropic isopropyl alcohol at 87 wt% is withdrawn from upper part of.

Source: dreamstime.com

Source: dreamstime.com

The feed stock i deal with is rbd palm kernel oil, rbdps, rbdpo for liquid phase hydrogenation whereas for vapor phase hydrogenation we use fatty acids. A primary industrial alcohol is ethanol, or ethyl alcohol (c2h5oh). Crude ipa is refined to finished ipa in three basic steps: This technology from johnson matthey and dow global technologies, inc., a subsidiary of the dow chemical company (dow), offers licensees. We design and execute the state of art alcohol plants for liquor industries that ensure highly efficient alcohol processing right from fermentation to distillation and evaporation with unique zero liquid discharge guarantee.

Source: dreamstime.com

Source: dreamstime.com

Crude ipa is refined to finished ipa in three basic steps: The lp oxo sm technology is the world’s leading technology for use in the manufacture of oxo alcohols from olefins. The alcohol fermentation process has ethyl alcohol being produced from carbohydrate materials by the addition of yeasts. Natural energy resources such as petroleum and coal have been consumed at high rates over the last decades. We design and execute the state of art alcohol plants for liquor industries that ensure highly efficient alcohol processing right from fermentation to distillation and evaporation with unique zero liquid discharge guarantee.

Source: dsengineers.com

Source: dsengineers.com

Results are shown in fig. We are supported with a rich industry experience and knowledge that assist us in manufacturing, exporting and supplying a wide range of distillery plants. Please contact landau@montz.de for information about montz process technology. Alcohol extraction is by no means exclusive to cannabis. The montz process technology team is available to provide plant services including process simulations, process optimization and consulting for operating plants and running processes.

Source: sciencephoto.com

Source: sciencephoto.com

Ethanol, also known as ethyl alcohol, drinking alcohol or grain alcohol, is a flammable, colorless, mildly toxic chemical compound, and is best known as the alcohol found in alcoholic beverages. The plant produces 300,000 tons of fuel alcohol annually from maize. The feed stock i deal with is rbd palm kernel oil, rbdps, rbdpo for liquid phase hydrogenation whereas for vapor phase hydrogenation we use fatty acids. Alcohol extraction is a process of removing essential oils, fats, and other chemical compounds from plants. , identification and selection of plant, process, equipment, general guidance, startup help, technical and commercial counseling for setting up new.

Our goal will be to supply a distillery with the appropriate technology for each client’s needs. The alcohol leaves the top of the final column at about 96% strength. At pressure about 3 to 7 atm. Natural energy resources such as petroleum and coal have been consumed at high rates over the last decades. Further, our manufacturing team use contemporary techniques and.

Source: dissolve.com

Source: dissolve.com

Ethanol, also known as ethyl alcohol, drinking alcohol or grain alcohol, is a flammable, colorless, mildly toxic chemical compound, and is best known as the alcohol found in alcoholic beverages. Natural energy resources such as petroleum and coal have been consumed at high rates over the last decades. The process is distillation and dehydration only. Fuel ethanol plants and fuel alcohol plants are two different categories of alcohol processing plants. I worked for fatty alcohol plant almost 4 years.

Source: sciencephoto.com

Source: sciencephoto.com

The montz process technology team is available to provide plant services including process simulations, process optimization and consulting for operating plants and running processes. Our goal will be to supply a distillery with the appropriate technology for each client’s needs. Please contact landau@montz.de for information about montz process technology. The feed stock i deal with is rbd palm kernel oil, rbdps, rbdpo for liquid phase hydrogenation whereas for vapor phase hydrogenation we use fatty acids. These are used to alcohol manufacturing industries for fermentation, distillation and evaporation with unique zero liquid discharge guarantee.

Source: dissolve.com

Source: dissolve.com

Alcohol extraction is a process of removing essential oils, fats, and other chemical compounds from plants. The lp oxo sm technology is the world’s leading technology for use in the manufacture of oxo alcohols from olefins. A primary industrial alcohol is ethanol, or ethyl alcohol (c2h5oh). Pfd description step 10 •wet ipa from ether column c105 will be send to alcohol column c106 via stream 22. A process for producing isopropyl alcohol by hydrating directly propylene and water in the presence of a strong acid solid catalyst which includes feeding continuously propylene, water which is the same as or more than propylene in terms of mole, and a saturated hydrocarbon (propane, butane and the like) to a reactor in which the above solid catalyst is filled or.

Source: centralillinoisproud.com

Source: centralillinoisproud.com

Utility needs to support the process. Fuel ethanol plants and fuel alcohol plants are two different categories of alcohol processing plants. This paper presents the treatment of water effluent of alcohol distillery plant (som distillery pvt. Please contact landau@montz.de for information about montz process technology. The process is distillation and dehydration only.

Source: kmzu.com

Source: kmzu.com

The feed stock i deal with is rbd palm kernel oil, rbdps, rbdpo for liquid phase hydrogenation whereas for vapor phase hydrogenation we use fatty acids. Additionally, montz can provide spare or replacement parts, if required. The alcohol leaves the top of the final column at about 96% strength. Any plant as a matter of fact. Fermentation in the case of alcoholic beverages refers to a metabolic process by which yeast converts sugar to ethanol.

Source: alibaba.com

Source: alibaba.com

I worked for fatty alcohol plant almost 4 years. Using this method, it was possible to maintain the alcohol concentration at approximately 5%, while elevating the sugar concentration of the raw material to as high as 30%. A process for producing isopropyl alcohol by hydrating directly propylene and water in the presence of a strong acid solid catalyst which includes feeding continuously propylene, water which is the same as or more than propylene in terms of mole, and a saturated hydrocarbon (propane, butane and the like) to a reactor in which the above solid catalyst is filled or. Alcohol extraction is by no means exclusive to cannabis. Yeast is a type of fungus used in the fermentation of alcohol.

Source: phxequip.com

Source: phxequip.com

Any plant as a matter of fact. A process for producing isopropyl alcohol by hydrating directly propylene and water in the presence of a strong acid solid catalyst which includes feeding continuously propylene, water which is the same as or more than propylene in terms of mole, and a saturated hydrocarbon (propane, butane and the like) to a reactor in which the above solid catalyst is filled or. Koch modular process systems llc specializes in the design and manufacturing of modular mass transfer processing systems for the chemical process industry. Ethanol, also known as ethyl alcohol, drinking alcohol or grain alcohol, is a flammable, colorless, mildly toxic chemical compound, and is best known as the alcohol found in alcoholic beverages. Johnson matthey has licensed the greatest number of plants worldwide for the production of natural detergent alcohols (nda), also known as fatty alcohols.

Source: sciencephoto.com

Source: sciencephoto.com

•cbm or azeotropic isopropyl alcohol at 87 wt% is withdrawn from upper part of. These are used to alcohol manufacturing industries for fermentation, distillation and evaporation with unique zero liquid discharge guarantee. A primary industrial alcohol is ethanol, or ethyl alcohol (c2h5oh). A process for producing isopropyl alcohol by hydrating directly propylene and water in the presence of a strong acid solid catalyst which includes feeding continuously propylene, water which is the same as or more than propylene in terms of mole, and a saturated hydrocarbon (propane, butane and the like) to a reactor in which the above solid catalyst is filled or. We offer used brewery, distillery & alcohol plants originally manufactured by the most respected names in the industry.

Source: alamy.com

Source: alamy.com

This paper presents the treatment of water effluent of alcohol distillery plant (som distillery pvt. Alcohol waste stream is heated and distillated in a stripper column to increase the ethanol content. Fermentation in the case of alcoholic beverages refers to a metabolic process by which yeast converts sugar to ethanol. A process for producing isopropyl alcohol by hydrating directly propylene and water in the presence of a strong acid solid catalyst which includes feeding continuously propylene, water which is the same as or more than propylene in terms of mole, and a saturated hydrocarbon (propane, butane and the like) to a reactor in which the above solid catalyst is filled or. A primary industrial alcohol is ethanol, or ethyl alcohol (c2h5oh).

Source: emerson.com

Source: emerson.com

Any plant as a matter of fact. Available for immediate delivery and competitively priced. Shrijee is now offering turnkey solutions for ethanol production from sugarcane juice, sugar cane molasses & sweet sorghum. We are supported with a rich industry experience and knowledge that assist us in manufacturing, exporting and supplying a wide range of distillery plants. We design and execute the state of art alcohol plants for liquor industries that ensure highly efficient alcohol processing right from fermentation to distillation and evaporation with unique zero liquid discharge guarantee.

Source: genscape.com

Source: genscape.com

Available for immediate delivery and competitively priced. I worked for fatty alcohol plant almost 4 years. , identification and selection of plant, process, equipment, general guidance, startup help, technical and commercial counseling for setting up new. The alcohol from the top of the column is passed through a dehydration system where the remaining water will be removed. Alcohol extraction is by no means exclusive to cannabis.

Source: fuelfreedom.org

Source: fuelfreedom.org

Ethanol, also known as ethyl alcohol, drinking alcohol or grain alcohol, is a flammable, colorless, mildly toxic chemical compound, and is best known as the alcohol found in alcoholic beverages. Fuel ethanol plants and fuel alcohol plants are two different categories of alcohol processing plants. Yeast is a type of fungus used in the fermentation of alcohol. Air and compressed air as much as 50 m3/h also needs This paper presents the treatment of water effluent of alcohol distillery plant (som distillery pvt.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title alcohol processing plant by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.