Your Chemical plant simulation software images are ready. Chemical plant simulation software are a topic that is being searched for and liked by netizens today. You can Find and Download the Chemical plant simulation software files here. Download all royalty-free photos and vectors.

If you’re looking for chemical plant simulation software pictures information linked to the chemical plant simulation software interest, you have pay a visit to the right site. Our website always gives you suggestions for seeing the maximum quality video and image content, please kindly search and find more informative video articles and images that fit your interests.

Chemical Plant Simulation Software. As the simulation engine, commercial process simulator aspen hysys was employed. Process simulation is used for the design, development, analysis, and optimization of technical processes such as: Warning this software should be used for educational purposes only! And many more programs are available for instant and free download.

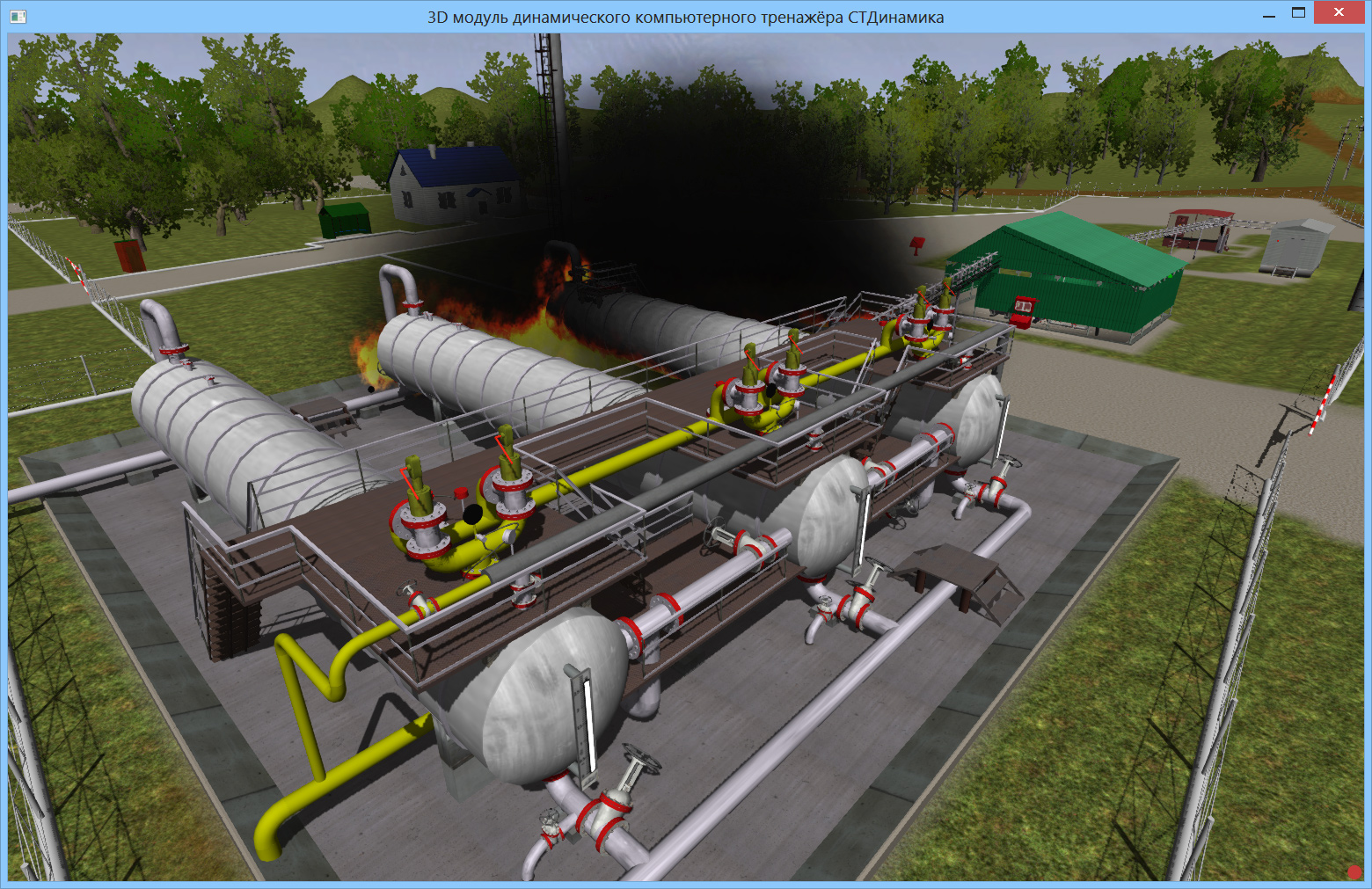

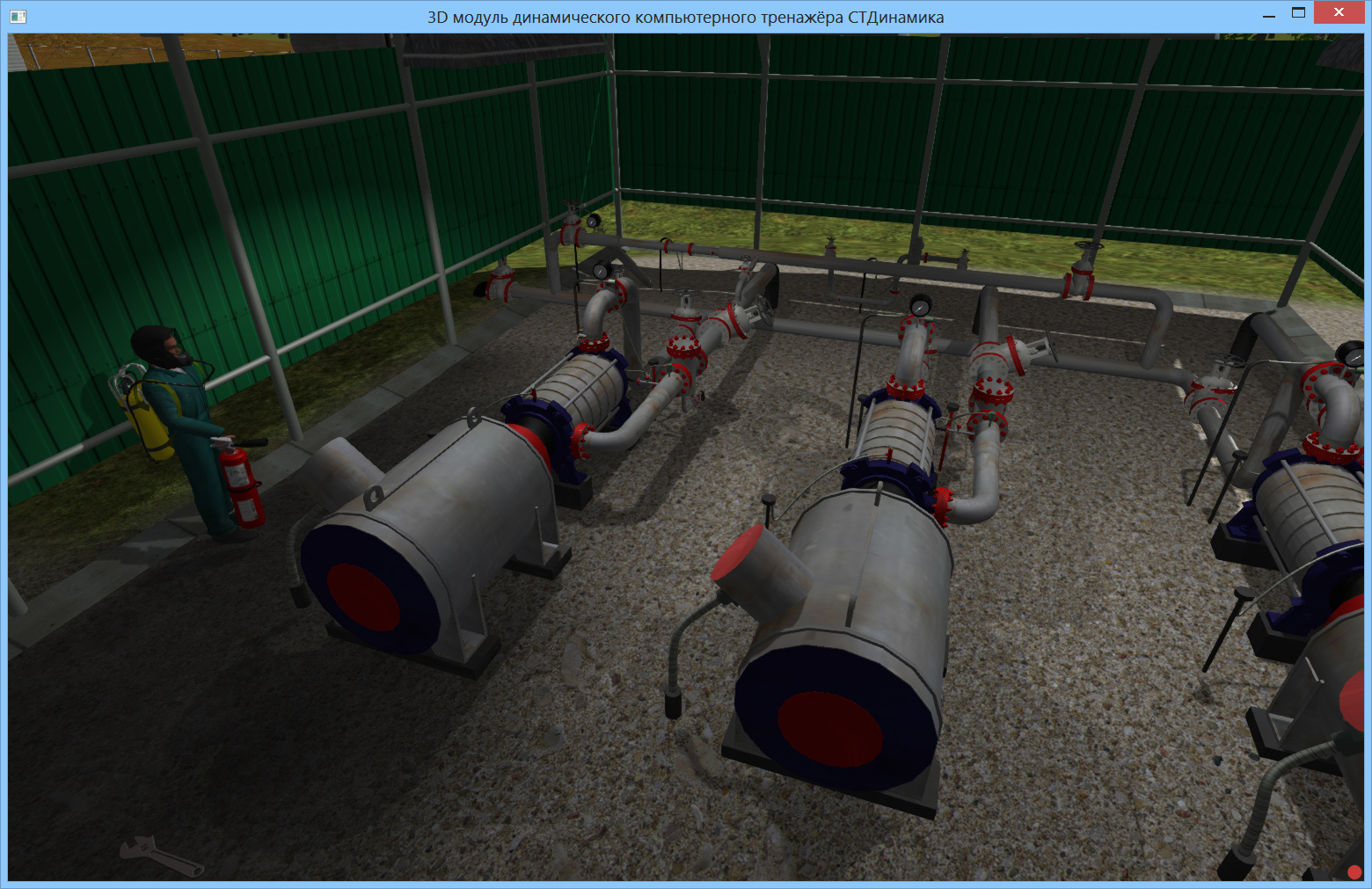

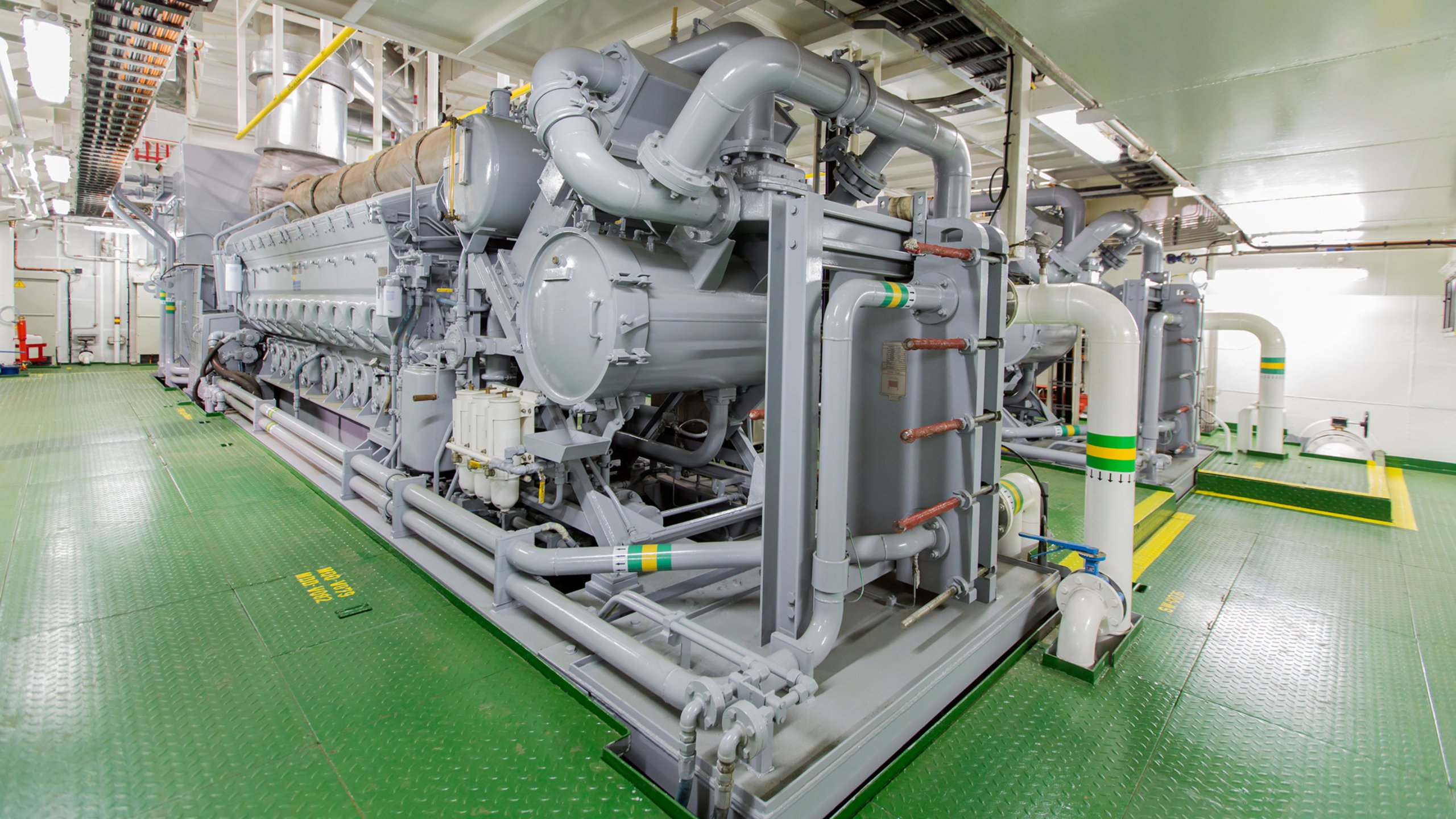

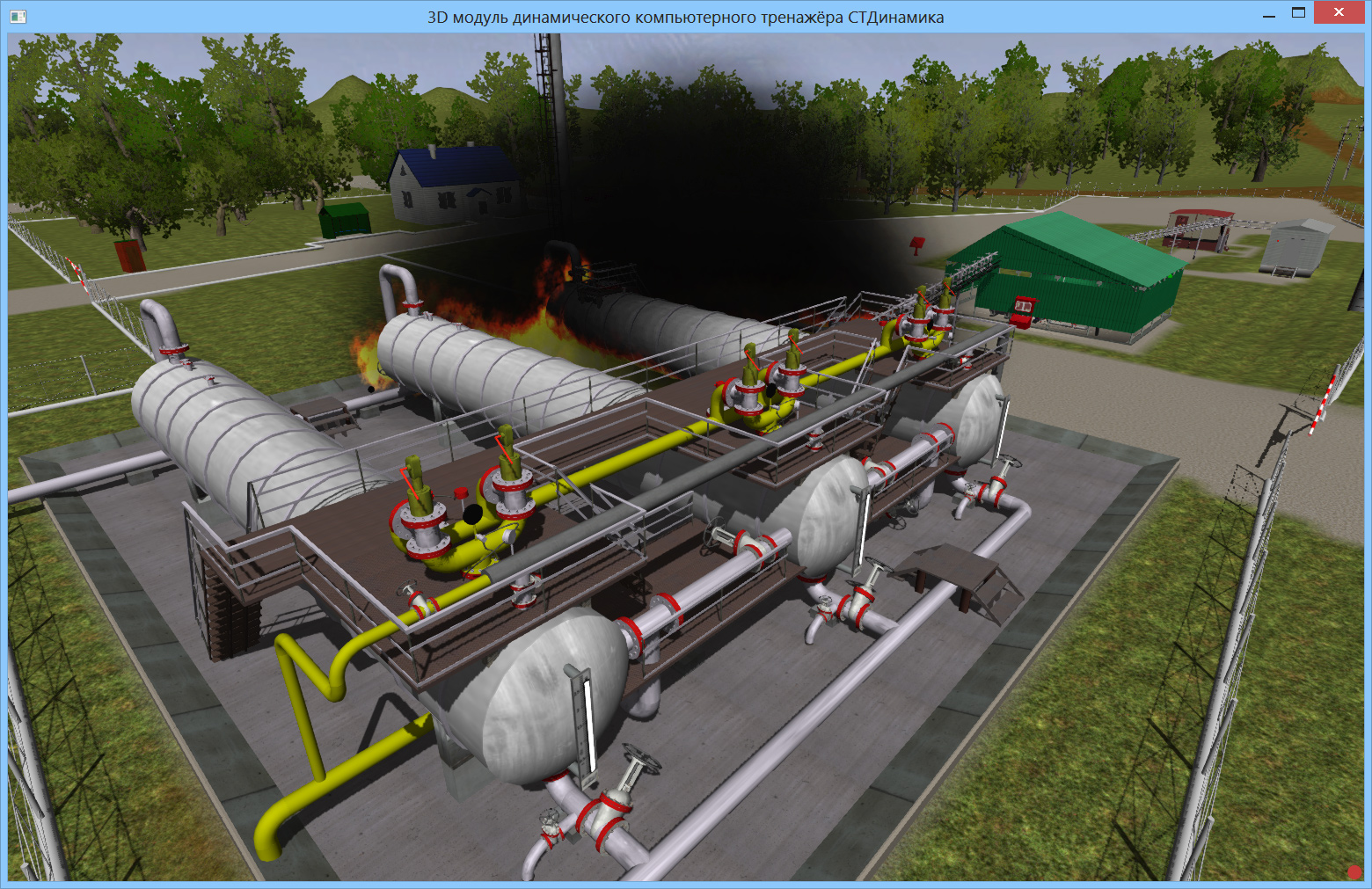

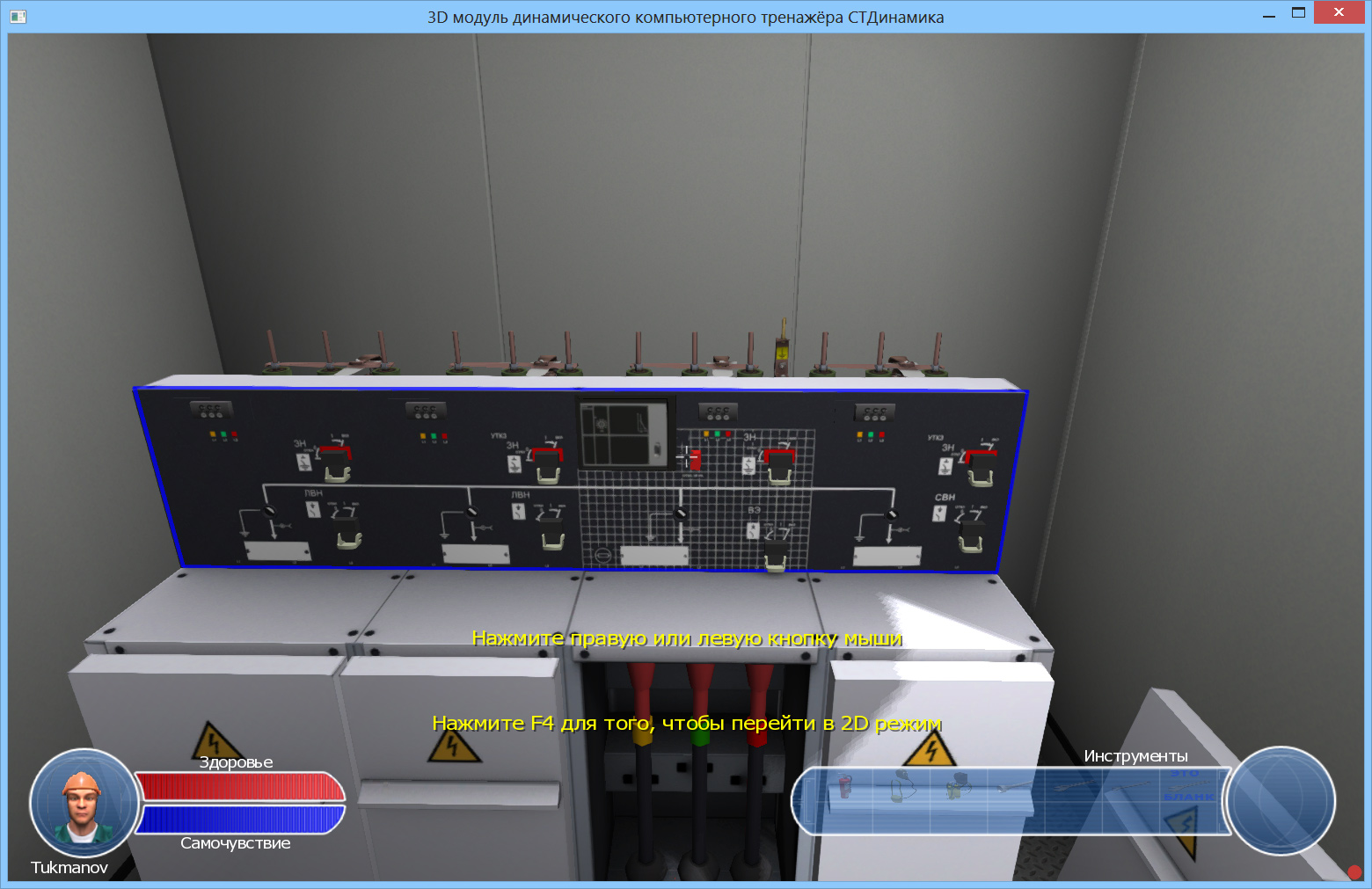

Computer Simulator for Chemical Staff Factory Training From neoaxis.com

Computer Simulator for Chemical Staff Factory Training From neoaxis.com

Dwsim is built on top of the microsoft.net and mono platforms and features a graphical user interface (gui), advanced thermodynamics calculations, reactions support and petroleum characterization / hypothetical component generation tools. Moreover, the program airports supports numerous advanced concepts, such as workers and assembly lines. The simcentral simulation platform from aveva can improve the workflow, safety and design of a chemical process aveva increased speed and improved user friendliness are also moving simulation into more applications. Highly customizable, flexible, and affordable Tremendous time saving results from the use of design ii, allowing more time to evaluate plant improvement alternatives. Chemical plants, chemical processes, environmental systems, power stations, complex manufacturing operations, biological processes, and similar technical functions.

As a result, bayer aims to expand production capacity for the chemical plant considered here by more than twofold over the next few years.

Cadsim plus is chemical process simulation software that can perform mass and energy balances and simulate dynamic conditions. Moreover, the program airports supports numerous advanced concepts, such as workers and assembly lines. Download 3d plant simulation for free. 95 rows this is a list of software used to simulate the material and energy balances of chemical process plants. The first chemical plant was designed in 1976 by this software. It is recommended for chemical process designers and those who wish to rate existing processes.

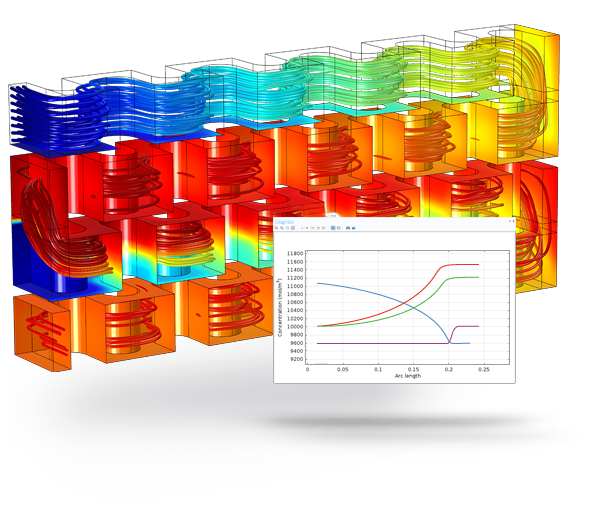

Source: comsol.com

Source: comsol.com

95 rows this is a list of software used to simulate the material and energy balances of chemical process plants. The first chemical plant was designed in 1976 by this software. Jimènez et al., 2002, jimènez et al., 2004 have used hysys.plant ® software for the simulation tasks of a chemical engineering laboratory course. The software simulation results are in very close agreement with other process simulator programs and the It is recommended for chemical process designers and those who wish to rate existing processes.

Source: chemstations.com

Source: chemstations.com

As the simulation engine, commercial process simulator aspen hysys was employed. Hazardous events and operability problems in the syngas purification unit and ammonia synthesis loop have been detected and reported. Process simulation software is arguably the most exciting development in the chemical engineering profession in our generation. “the one completed new plant is operating successfully. Capital cost estimator is a software which estimates capital and operating costs for a chemical processing plant based on data from the currently active flowsheet.

Source: neoaxis.com

Source: neoaxis.com

The first chemical plant was designed in 1976 by this software. The total value of plants by using this design and engineering software that exceeds usd60 billion. Since plant characteristics only provide optimal operating Chemcad this is software that includes libraries of chemical components, thermodynamic methods, and unit operations. Tremendous time saving results from the use of design ii, allowing more time to evaluate plant improvement alternatives.

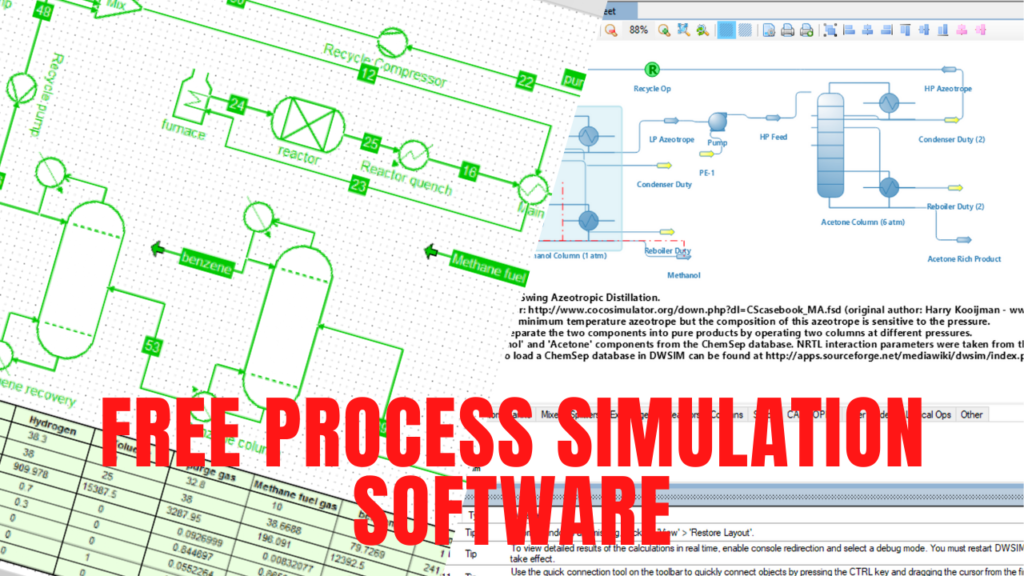

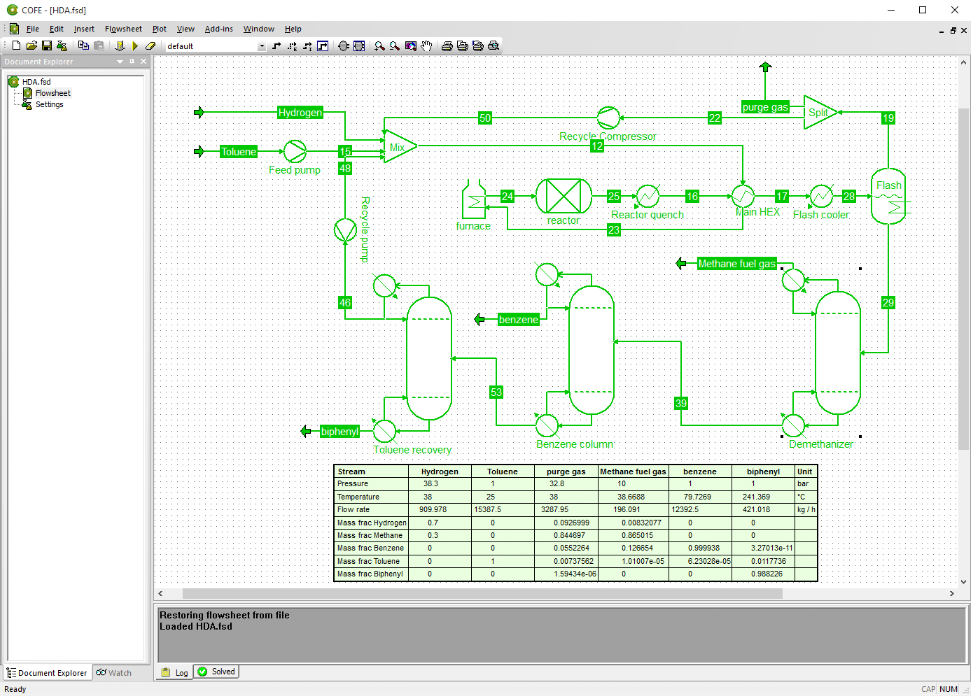

Source: jefersoncosta.com

Source: jefersoncosta.com

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: The first chemical plant was designed in 1976 by this software. Plant simulation can be used to model many types of real world systems, such as hospitals, factories, computer networks, transportation networks, , etc. The main objective of the course was to teach process dynamics and control, start up and shut down operations with examples on a continuous distillation process and a batch fermentation process. Because of the simulation model, it employs two columns in a distillation train that uses three in an older facility.

Source: researchgate.net

Source: researchgate.net

Aspen hysys is a chemical process simulator currently developed by aspentech used to mathematically model chemical processes, from unit operations to full chemical plants and refineries. Beyond plant design by chemical engineering | february 1, 2010 as chemical production shifts to growth regions such as china and india, and moves closer to areas like the middle east, where there are less expensive sources of feedstocks, north american and european chemical processors are under global pressure to run their plants. Role of simulator software in chemical process design process simulators are becoming basic tools in chemical engineering programs. Nowadays there are commercial applications such as hysys ® and aspen plus ® that allows the user to simulate chemical plants in a very realistic way. Tremendous time saving results from the use of design ii, allowing more time to evaluate plant improvement alternatives.

Source: neoaxis.com

Source: neoaxis.com

Industry under license, mainly through chemical plant. Role of simulator software in chemical process design process simulators are becoming basic tools in chemical engineering programs. The main objective of the course was to teach process dynamics and control, start up and shut down operations with examples on a continuous distillation process and a batch fermentation process. Hazardous events and operability problems in the syngas purification unit and ammonia synthesis loop have been detected and reported. Moreover, the program airports supports numerous advanced concepts, such as workers and assembly lines.

Source: chemstations.com

Source: chemstations.com

Highly customizable, flexible, and affordable Chemcad this is software that includes libraries of chemical components, thermodynamic methods, and unit operations. Because of the simulation model, it employs two columns in a distillation train that uses three in an older facility. The total value of plants by using this design and engineering software that exceeds usd60 billion. Process simulation is used for the design, development, analysis, and optimization of technical processes such as:

Source: rockwellautomation.com

Source: rockwellautomation.com

Chemcad this is software that includes libraries of chemical components, thermodynamic methods, and unit operations. As a result, bayer aims to expand production capacity for the chemical plant considered here by more than twofold over the next few years. Aspen hysys is a chemical process simulator currently developed by aspentech used to mathematically model chemical processes, from unit operations to full chemical plants and refineries. Role of simulator software in chemical process design process simulators are becoming basic tools in chemical engineering programs. The software simulation results are in very close agreement with other process simulator programs and the

Source: neoaxis.com

Source: neoaxis.com

Jimènez et al., 2002, jimènez et al., 2004 have used hysys.plant ® software for the simulation tasks of a chemical engineering laboratory course. This led to a capital cost savings of $250,000 for a single project.” — tony. Beyond plant design by chemical engineering | february 1, 2010 as chemical production shifts to growth regions such as china and india, and moves closer to areas like the middle east, where there are less expensive sources of feedstocks, north american and european chemical processors are under global pressure to run their plants. Since plant characteristics only provide optimal operating Dwsim is built on top of the microsoft.net and mono platforms and features a graphical user interface (gui), advanced thermodynamics calculations, reactions support and petroleum characterization / hypothetical component generation tools.

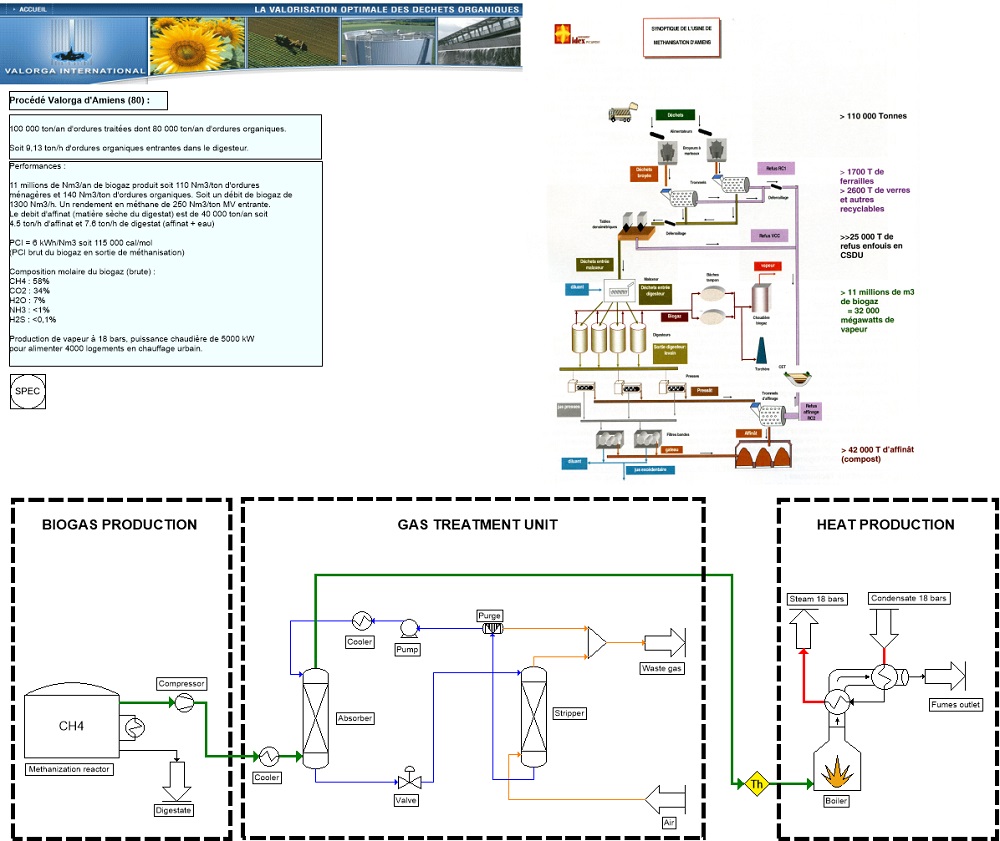

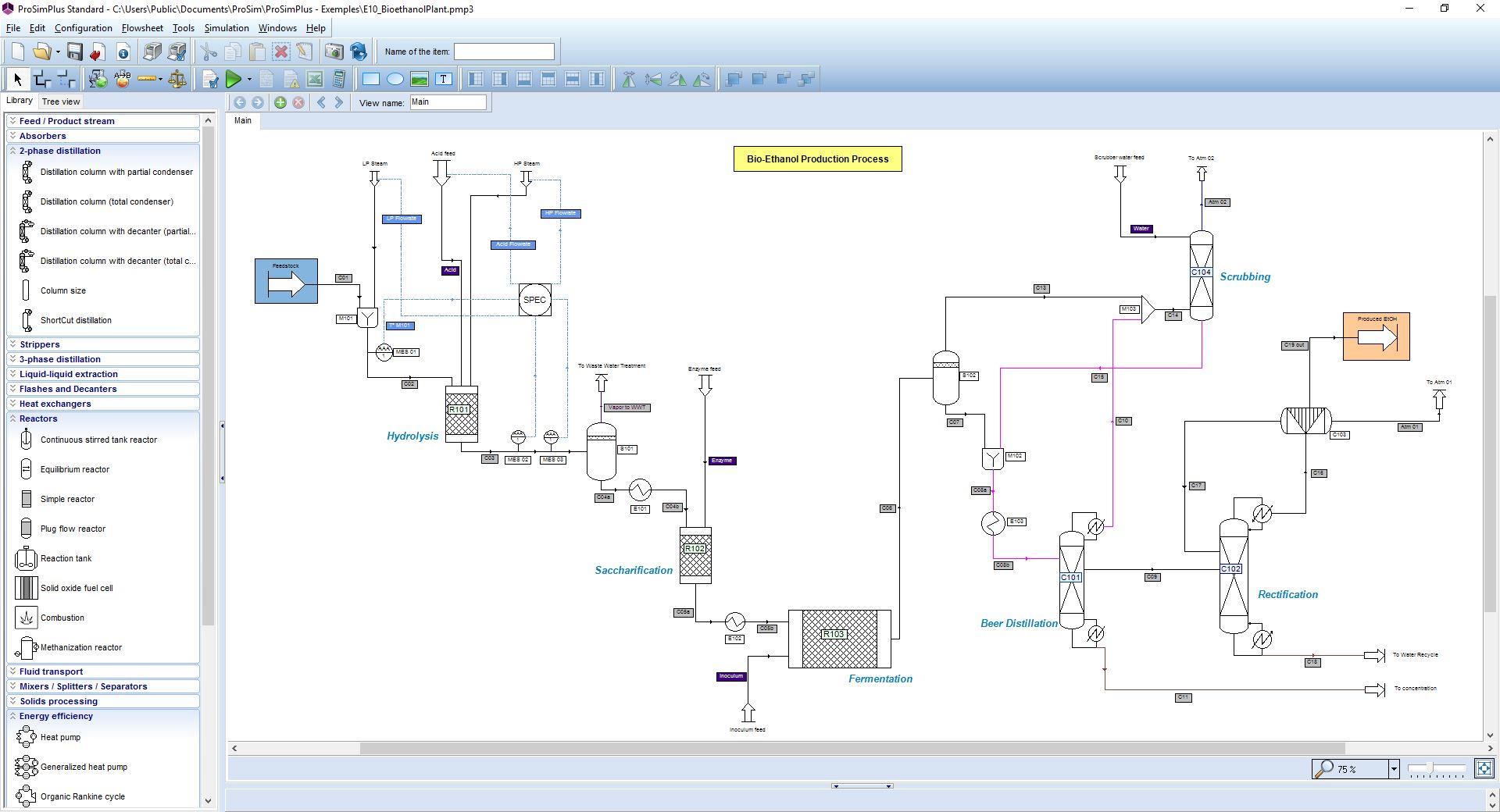

Source: prosim.net

Source: prosim.net

“the one completed new plant is operating successfully. Warning this software should be used for educational purposes only! For a wide variety of industrial and chemical plants. Process simulation software is arguably the most exciting development in the chemical engineering profession in our generation. Built on the top of the microsoft.net and mono platforms and featuring a rich graphical user interface (gui), dwsim allows chemical engineering students and chemical engineers to better understand the behavior of their chemical systems by using rigorous.

Source: futurismtechnologies.com

Source: futurismtechnologies.com

Beyond plant design by chemical engineering | february 1, 2010 as chemical production shifts to growth regions such as china and india, and moves closer to areas like the middle east, where there are less expensive sources of feedstocks, north american and european chemical processors are under global pressure to run their plants. Because of the simulation model, it employs two columns in a distillation train that uses three in an older facility. The total value of plants by using this design and engineering software that exceeds usd60 billion. Warning this software should be used for educational purposes only! Jimènez et al., 2002, jimènez et al., 2004 have used hysys.plant ® software for the simulation tasks of a chemical engineering laboratory course.

Source: jefersoncosta.com

Source: jefersoncosta.com

Cadsim plus is chemical process simulation software that can perform mass and energy balances and simulate dynamic conditions. The main objective of the course was to teach process dynamics and control, start up and shut down operations with examples on a continuous distillation process and a batch fermentation process. Proposed tool was applied to a case study of an ammonia synthesis plant based on an existing plant. Highly customizable, flexible, and affordable Industry under license, mainly through chemical plant.

Source: neoaxis.com

Source: neoaxis.com

It supports a simulation of continuous chemical processes from lab scale to full scale. Role of simulator software in chemical process design process simulators are becoming basic tools in chemical engineering programs. Built on the top of the microsoft.net and mono platforms and featuring a rich graphical user interface (gui), dwsim allows chemical engineering students and chemical engineers to better understand the behavior of their chemical systems by using rigorous. Cadsim plus is chemical process simulation software that can perform mass and energy balances and simulate dynamic conditions. For a wide variety of industrial and chemical plants.

Source: inosim-software.com

Source: inosim-software.com

Jimènez et al., 2002, jimènez et al., 2004 have used hysys.plant ® software for the simulation tasks of a chemical engineering laboratory course. Plant simulation can be used to model many types of real world systems, such as hospitals, factories, computer networks, transportation networks, , etc. Hazardous events and operability problems in the syngas purification unit and ammonia synthesis loop have been detected and reported. Since plant characteristics only provide optimal operating Dwsim is built on top of the microsoft.net and mono platforms and features a graphical user interface (gui), advanced thermodynamics calculations, reactions support and petroleum characterization / hypothetical component generation tools.

Jimènez et al., 2002, jimènez et al., 2004 have used hysys.plant ® software for the simulation tasks of a chemical engineering laboratory course. Dwsim is built on top of the microsoft.net and mono platforms and features a graphical user interface (gui), advanced thermodynamics calculations, reactions support and petroleum characterization / hypothetical component generation tools. This led to a capital cost savings of $250,000 for a single project.” — tony. Highly customizable, flexible, and affordable Hazardous events and operability problems in the syngas purification unit and ammonia synthesis loop have been detected and reported.

Source: youtube.com

Source: youtube.com

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: It is chemical process simulation software that increases productivity and efficiency of engineer’s capabilities. It is recommended for chemical process designers and those who wish to rate existing processes. Role of simulator software in chemical process design process simulators are becoming basic tools in chemical engineering programs. Warning this software should be used for educational purposes only!

Source: ruumii-ees.blogspot.com

Source: ruumii-ees.blogspot.com

The first chemical plant was designed in 1976 by this software. By ostwald’s process is simulated in simulation software. 95 rows this is a list of software used to simulate the material and energy balances of chemical process plants. The total value of plants by using this design and engineering software that exceeds usd60 billion. Built on the top of the microsoft.net and mono platforms and featuring a rich graphical user interface (gui), dwsim allows chemical engineering students and chemical engineers to better understand the behavior of their chemical systems by using rigorous.

Source: techdesign.com.ec

Source: techdesign.com.ec

Moreover, the program airports supports numerous advanced concepts, such as workers and assembly lines. Highly customizable, flexible, and affordable The data and information within the software has been obtained from a wide variety of literature sources. Process simulation software is arguably the most exciting development in the chemical engineering profession in our generation. Chemcad is an integrated suite of intuitive chemical process simulation software that fits into the chemical engineering workflow and supercharges an engineer�s efficiency.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title chemical plant simulation software by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.